The chain conveyor is intended for the horizontal transportation of bulk materials such as cereal grains, oil and legume seeds, raw materials for the production of feed, biomasses, ash and dust.

The devices presented below are used in industries such as:

woodworking, port, feed, cereal storage facilities, milling, oil extractor presses.

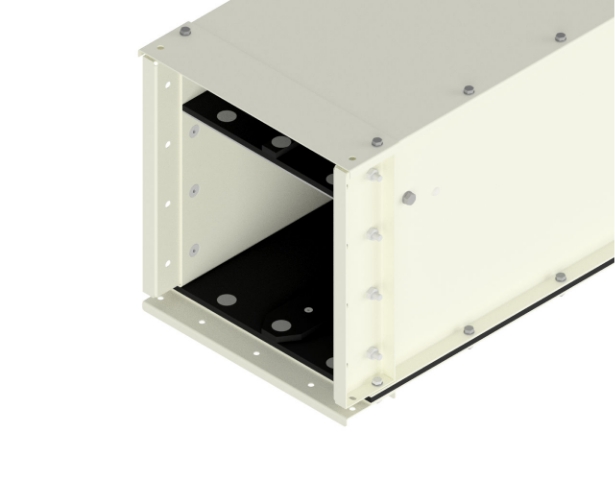

Chain conveyors are assembled from ready-made modules:

drive station, inner segments, tension station and chain. This allows the assembling of chain conveyors with lengths of up to 85 m.

The bottom and the top deck of conveyors are lined with anti-static abrasion- resistant PE1000 or PUGA material. The lining thickness is selected according to the conveyor capacity and the type of material being conveyed, but the minimum thickness we use is 10 mm.

As standard, our conveyors are made of Z275 galvanised steel sheet, but optionally they can also be made of S235 steel, powder-coated in RAL colours, or of acid-resistant steels such as AISI 304, AISI 316 and HARDOX.

Drive stations are available in versions:

Inner segments are available in versions:

Tensioning stations are available in versions:

Chain type V-TS-R All chain elements manufactured by our company are made on numerically controlled machine tools, which ensures the highest quality and repeatability of the links. Thanks to the special V-shaped chain design, we have an advantage over the competition, guaranteeing that the chain cannot come undone during operation and 2 times higher breaking forces than standard chains used in conveyors of the same performance. Components such as pins and bushings are subjected to a special thermo-chemical treatment to ensure the highest quality and long-term trouble-free operation.

Our standard is to equip conveyors with electrical sensors, ensuring the highest health and safety standards, and reliable operation. The sensors used indicate incorrect chain tension, conveyor overflow, opening of inspection flaps.

Chains type V-TS-R produced by our company are characterized by high reliability and failure-free operation.

We have been manufacturing this type of chain continuously for over 30 years with due diligence, controlling the production process at every stage. Thanks to the use of CNC machines, we are able to provide the highest quality standards. That's why our chains average 7,500,000 tons of grain over their lifetime.

We obtain the highest quality thanks to the use of certified materials and special thermal and chemical treatment to which the pins and bushings of our chains are subjected.

Highlights: