The bucket elevator is intended for the horizontal transportation of bulk materials such as cereal grains, oil and legume seeds, raw materials for the production of feed, biomasses, ash and dust.

The devices presented below are used in industries such as:

woodworking, port, feed, cereal storage facilities, milling, oil extractor presses.

Long service life,

the design of the device and the materials used ensure that our bucket elevators run continuously for years without the need to repair. In addition, the elevators are protected by a number of sensors to control the correct operation. All of this guarantees years of trouble-free operation.

Solid and rigid structure,

the advantage of our bucket elevators is an innovative system for connecting pipes to each other, using special fasteners and ISO 10642 flat countersunk head bolts. This ensures the high rigidity of the entire structure and easy installation.

Complete dust-tightness

all components are screwed with the use of special seals which guarantee 100% tightness of our equipment, even those operating at an overpressure.

Easy operation

multiple inspection and service hatches and the tensioner scaled on both sides make it easy to use and clean the equipment every day.

RYBIŃSKI s.c. offers bucket elevators with capacities ranging from 20 t/h to 220 t/h

Boots are available in the following versions:

Standard – provided with multiple openings for inspection of the inside of the boot and drawers to clean the bottom of the boot.

Self-cleaning – provided with multiple openings for inspection of the inside of the boot and an anti-dead zone curve between the buckets and the bottom of the boot.

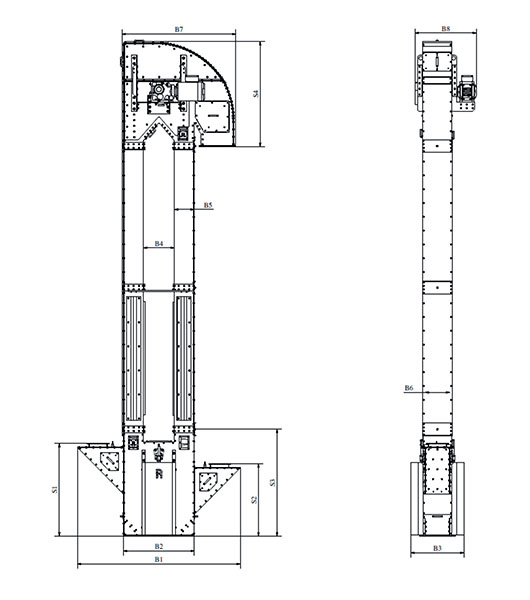

The head is made as a screwed structure with multiple openings for the inspection of the inside of the device. The components exposed to abrasion are protected with an abrasion-resistant material. As standard, the top cover of the head is made of AISI 304 steel and provided with lugs to attach crane/ winch ropes for safe assembly.

Pipes are made from one section of a metal sheet using a CNC laser and bent on the CNC bending brake into a U-shape. They are covered by screwed covers. Pipes are joined with special fasteners which guarantee the straightness of the entire elevator structure. Each pipe can be opened for cleaning.

Service pipes are used for the easy and quick installation of buckets on the belt, and their design ensures that the front cover can be opened. In addition, a service hatch is provided in the rear wall and reinforcements are mounted on the side walls so that the pipe is provided with sufficient support when opened.

Wide range of belts to convey various materials.

Detailed technical support.

Large stock.

The offered belts are narrowed, shortened and drilled with holes to meet customer requirements.

If necessary, the belts in stock are sent on the same day.

We have a very large range of elevator buckets. We offer over 400 different sizes and types of elevator buckets for each type of product and application.

Carbon and stainless steel elevator buckets (stamped / seamless or assembled).

Plastic / non-metallic elevator buckets (nylon, HDP or PU).

Elevator buckets for agricultural applications (e.g. cereals, feed, seeds, sugar).

Elevator buckets for industrial applications (e.g. cement, lime, aggregates, coal, fertiliser).

As standard, we use NORD or SEW gear motors seated directly on the drive shaft to drive our bucket elevators.

Drive shaft bearings are mounted in SKF, SNR, KOYO pedestal bearing housings offset to the outside of the elevator frame. Lubrication points are outside the bearing unit covers.

The one-way clutch is installed in the head of the bucket elevator on the opposite side of the shaft to the gear motor. The purpose of the one-way clutch is to prevent the belt from moving in the opposite direction.

Straight version and Broken version with guide roller.